Rigid Bonding

Rigid bonding is a traditional bonding method where adhesive is applied to the surface of substrates that are then pressed together, and after time the two objects are strong and rigidly fixed. The adhesive layer between the objects is thin and hard. Load, stress and movement are transferred directly. Rigid bonding is recommended when bonding very similar materials that are not subjected to cyclic stress. Typical rigid adhesives are hard epoxy as well as water or solvent based products.

A Stiff Bond for Load Transfer

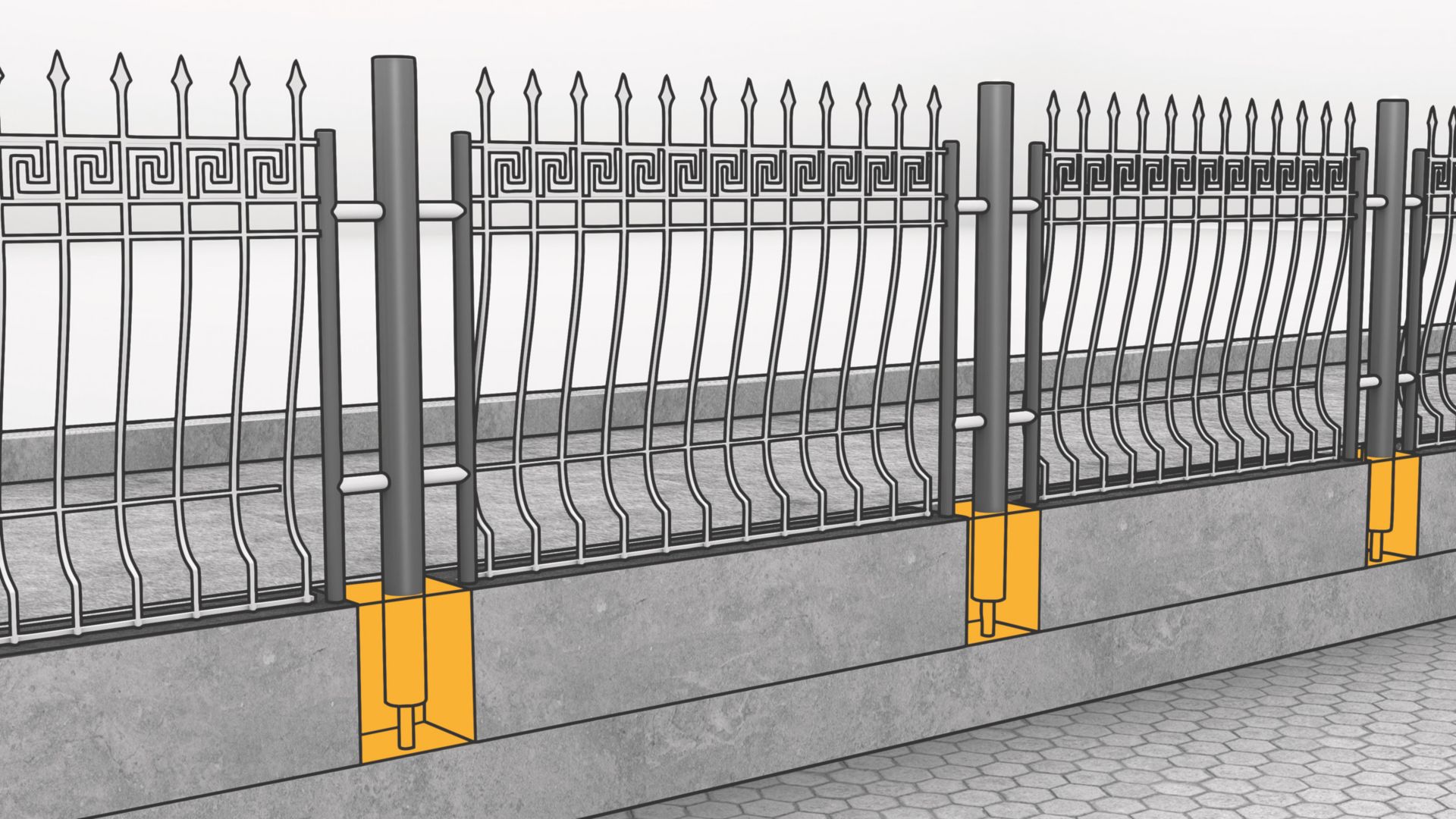

Combination of several elements with non-moving, stiff joints is important in various projects:

- Precast concrete parts

- Connection of different construction materials

- Application of strengthening systems

- Structural additions such as rails and curbstones

One Range for Many Substrates

The Sikadur® range covers adhesives, epoxy mortars and bonding bridges for various substrates:

- Hardened, green and fresh concrete

- Masonry and natural stone

- Steel and other metals

- Wood

- Fiber-reinforced polymer (FRP) materials

Concrete Elements

Sika provides a range of special epoxy adhesives for bonding large scale concrete segments during segmental bridge construction work. Other applications for bonding concrete elements with Sikadur® adhesives are important in areas including roofs, concrete pipes, retaining walls, tanks and more.

Steel, Carbon Fiber and Glass Fiber Elements

Sikadur® epoxy adhesives have been widely used since the 1960’s to bond steel plates on concrete structures. These special adhesives are also used to bond new or replacement parts and components onto concrete structures, as well as composite sections based on glass or carbon fiber.

New Concrete and Repair

In addition to adhesives for structural bonding of various substrates, Sika also offers bonding bridges for the connection of old and new concrete, as well as epoxy based mortars for fast repairs.